73

TECH

tip

by BLUE SEA SYSTEMS

THE NUTS AND BOLTS OF ANY ELECTRICAL SYSTEM ARE

THE CONNECTORS WHICH KEEP THE CURRENT FLOWING.

Blue Sea Systems connectors reduce heat and improve efficiency

and reliability in a boat’s electrical system.

The features below make Blue Sea Systems connectors stand out

from the others:

Tin-plated copper buses

provide maximum conductivity and

corrosion resistance.

Insert-molded stainless steel studs

eliminate the need

for securing nuts and allow high torquing for excellent electrical

contact.

UL 94-V0 rated base materials

resist high heat.

Terminal Screws

incorporate stainless steel split ring lock

washers and captive star-type lock washers keep connections

tight in high vibration environments.

One-Piece Serrated Flange Nuts

ensure correct and

secure connections

Optional insulating covers

meet ABYC and USCG

insulation requirements.

C

O N N E C T O R S A N D

I

N S U L A T O R S

TECH

tip

by BLUE SEA SYSTEMS

How a BusBar Should be Rated

Until now, there was no consistent method of rating busbars

which made it difficult to determine the appropriate busbar for

the application. The American Boating and Yacht Council (ABYC) is

considering adding busbar ratings to the Electrical Section E11. Other

organizations, including the Institute of Electrical and Electronics

Engineers (IEEE), currently offer guidance.

The IEEE states a busbar should be rated at the highest

amperage passing through any section of the busbar,

with a maximum of a 50° C rise in temperature from an

ambient temperature of 50° C.

Blue Sea Systems uses a more conservative threshold of a 40° C rise

in temperature since busbars are often located in hot engine rooms.

This rating method avoids excess terminal temperature at the wire

termination.

Factors Influencing BusBar Ampacity Ratings:

1) Material:

The rating of any busbar is based on both the cross

section of the bus and the material used. Blue Sea Systems

uses Tin-Plated Copper C11000 which has more than

3.5 times the electrical conductivity as brass, used by

some manufacturers.

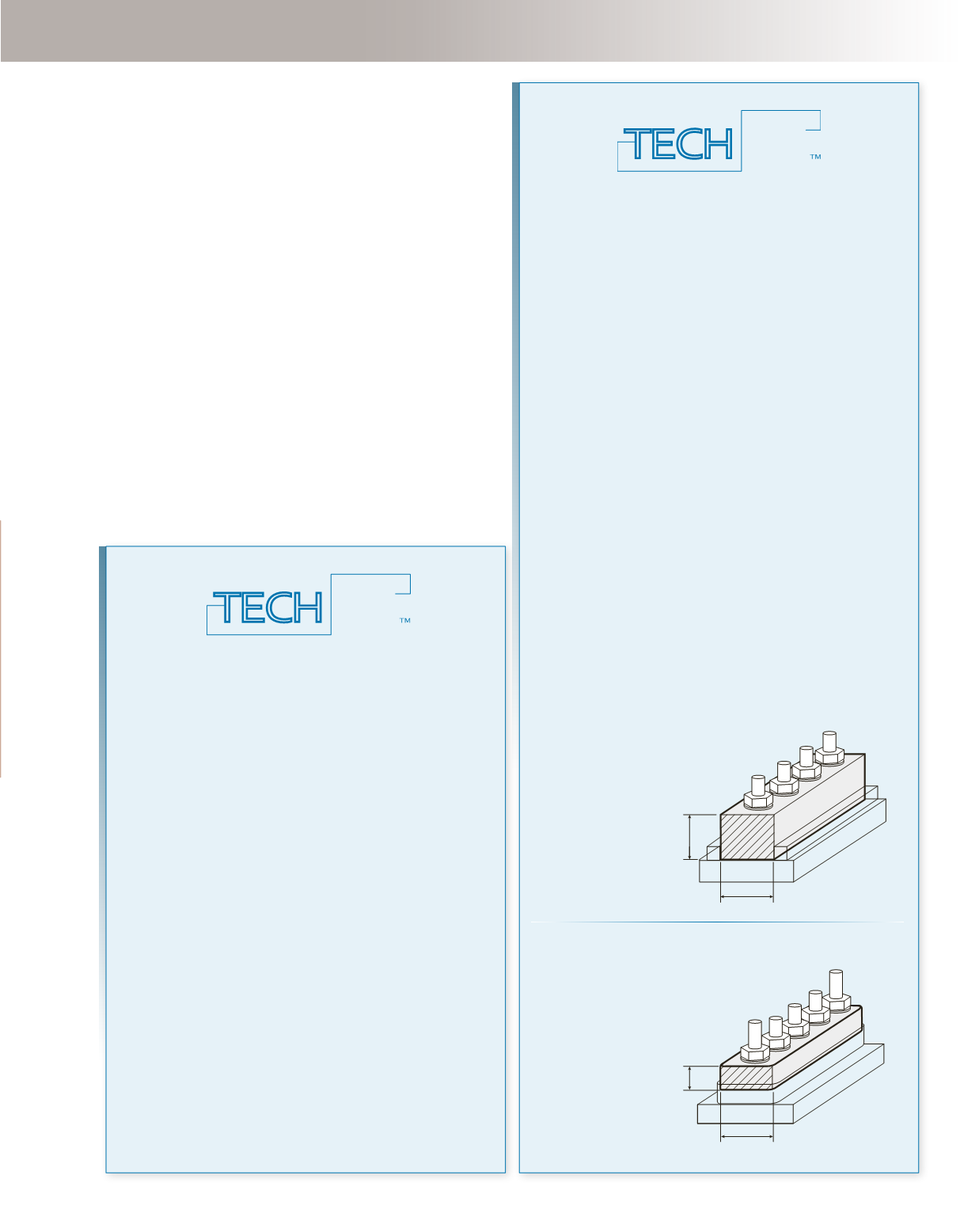

2) Cross Section:

A thicker cross section provides more material

for electron flow and a larger surface area for efficient cooling.

Carefully compare cross sections of a bus and do

not rely solely on published ratings.

19mm

25.5mm

7.5mm

25.5mm

Blue Sea Systems

BusBar Cross Section and

Ampacity Rating

19mm x 25.5mm = 484mm

Rating:

600A

Competitors

BusBar Cross Section and

Ampacity Rating

7.5mm x 25.5mm = 191mm

Published Rating:

650A

Application steps which improve busbar performance:

1) Optimize Current Flow:

the performance of a busbar can

be increased by attaching the primary feed wire to the center of

the busbar. The performance can be further increased by first

attaching the primary feed wire followed by the highest

load wire to the same terminal. This will allow the current to be

carried by the large cables and avoid sending all of the current

through the busbar. Although this will improve the performance

of the busbar, it does not change the actual ampacity rating of

the busbar and should not be used when comparing one

busbar to another.

2) Increase Voltage Capacity:

Most busbars have both an

amperage and voltage rating. Higher voltage can be

achieved by:

a.

Increasing the creepage distance, which is the distance from a

busbar mounting fastener to a grounded surface like a firewall.

Creepage distance directly impacts the voltage rating of the

busbar. Insulating the base and using insulating fasteners

rather than conductive fasteners will significantly increase

the safe operating voltage of a bus bar. The insulating system

including the creepage distance has to prevent failure in the

event of transients and surges in voltage.

b.

Managing the buildup of corrosion will significantly improve

the safety and service life of a busbar. No exposed busbar

can be expected to operate safely with a live connection in

a wet location. An exception would be busbars used for

lightening protection and grounding systems.