9

TECH

tip

by BLUE SEA SYSTEMS

BATTERIES ARE THE HEART OF THE ELECTRICAL SYSTEM.

Batteries are often the largest single expense in the electrical system

and are sensitive to failure and shortened life if not charged properly.

Modern battery chemistries – Gel, AGM, TPPL, Lithium Ion, and Flooded

Lead Acid (FLA) – require adherence to manufacturer’s charging

recommendations. Following these recommendations requires a battery

charger which is both rugged and sophisticated.

All battery manufacturers agree precise control of these

variables is critical:

· Voltage

· Time

· Temperature

Batteries may perform poorly and fail prematurely due to a charger's

failure to properly manage voltage, time, and temperature. A well

designed battery charger will allow these variables to be correctly set

for the requirements of each battery type and will manage them

properly in the charging process.

Five critical features that enable batteries to be charged

according to manufacturers' recommendations:

1. User Defined Charge Profiles (Voltages)

For setting the charger’s voltages to match the battery

manufacturer’s recommendations.

2. User Defined Absorption Stage Values

For determining when the charger should exit the Absorption Stage

in order to prevent overcharging.

3. Charge Coordination

To ensure Charging Relays (ACR) are not operating in conflict with

the charger. On shore power with a three bank charger, ACRs are

not required as they are when away from the dock and one alternator

must charge 3 battery banks.

4. PreFloat

™

– a Blue Sea Systems P12 exclusive (Patent Pending)

Allows each battery on a P12 Battery Charger to exit the Absorption

Stage when it is ready. Conventional chargers hold all three batteries

in Absorption Stage until all three are ready to exit. This subjects 1

or 2 batteries to higher voltages than necessary while waiting for the

3rd battery to complete the Absorption Stage.

5. Battery Temperature Compensation

For adjusting charging voltage up (for colder batteries) or down

(for warmer batteries) as recommended by almost all battery

manufacturers for proper battery performance. Temperature must be

determined by a sensor on the battery . Sensing the temperature

of the charger itself, as is done on some models, is useless for

battery voltage compensation.

These 5 critical functions, are important features of a battery charger

and rely on voltage, time, and temperature control to achieve Battery

Manufacturers' recommendations.

P

O W E R

C

O N V E R S I O N

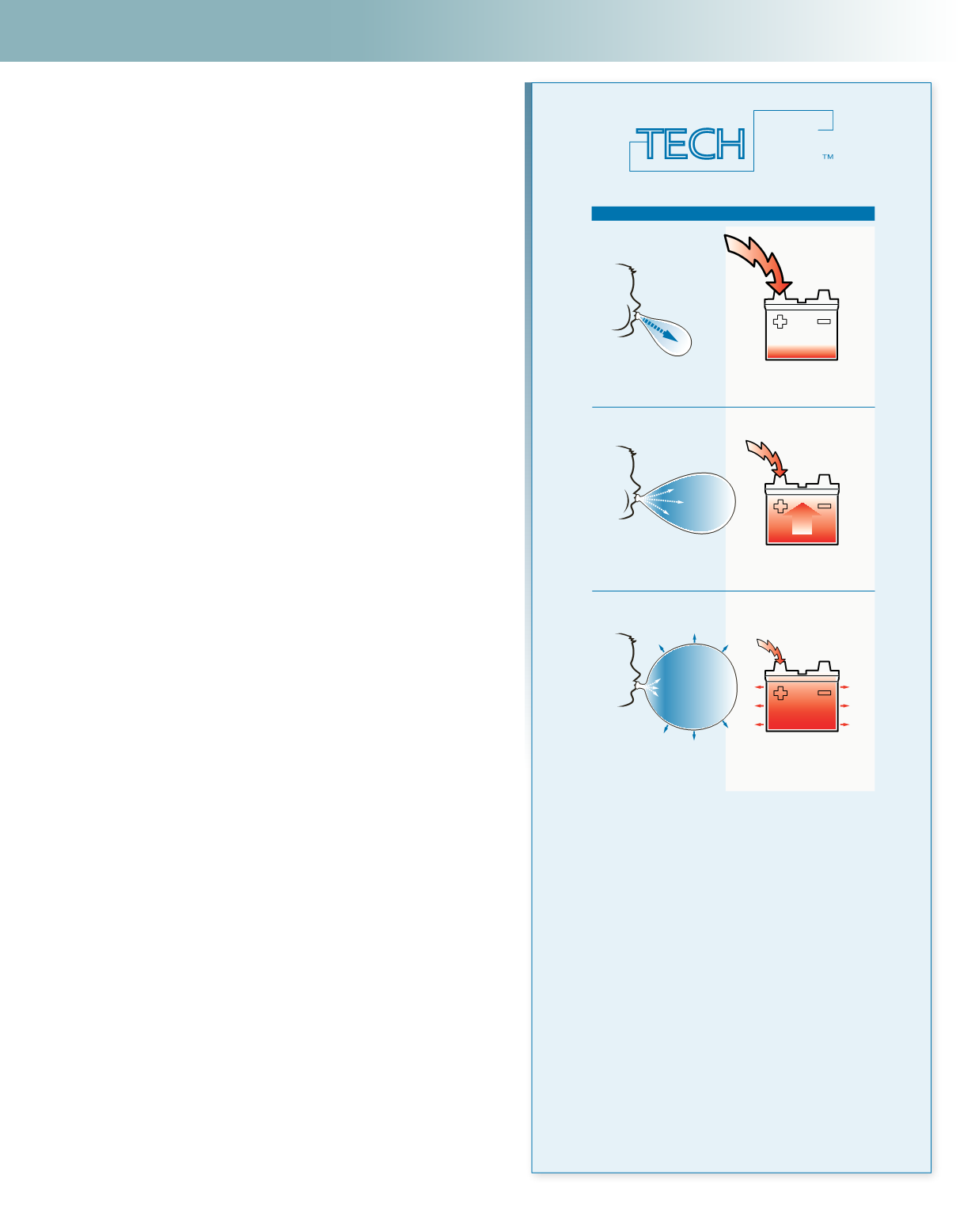

ELECTRICAL PRESSURE

AIR PRESSURE

BULK

Increasing air

pressure

Steady

electrical

pressure

High air volume

Steady amperage volume

Steady air

pressure

Increasing

electrical

pressure

Decreasing air volume

High amperage volume

Low

electrical

pressure

Small volume

(to offset leakage)

Small amperage volume

(to offset self discharge)

ABSORPTION

FLOAT

Battery Charging Explained

While not a perfect analogy, it is useful to think of voltage as

pressure. Just as applying too much pressure to a balloon

for too much time can ruin a balloon, applying too much

electrical pressure (voltage) ruins batteries.

Batteries are charged by applying a higher voltage

(electrical pressure) than a battery normally has. That forces

a chemical reaction in the battery that stores energy in

chemical form that is later turned into electrical energy

when power is required.

For this process to occur effectively, charging voltage must

be applied for the appropriate time and must be adjusted

up (for cold batteries) or down (for warm batteries).

A charger’s failure to properly manage these three variables

- VOLTAGE, TIME, and TEMPERATURE, results in batteries that

are chronically undercharged or overcharged. This delivers

less energy for the boater’s safety and comfort and results

in expensive premature failure of batteries.